Specification of WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine:

CNC Press Brake Bending Machine | WC67Y-160Tx3200 | Unit |

Nominal pressure | 1600 | KN |

Working table length | 3200 | mm |

Working table width | 200 | mm |

Throat depth | 320 | mm |

Distance between column | 2600 | mm |

Opening height | 450 | mm |

Slide block speed | Rapid down | 80 | mm/s |

Load speed | 10 | mm/s |

Return | 60 | mm/s |

Main power | 11 | KW |

Max. stroke for back gauge | 600 | mm |

Dimensions | L | 3500 | mm |

W | 1900 | mm |

H | 2560 | mm |

Weight |

| 9000 | kgs |

Installation environment of the WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine:

(1) Power supply voltage: 380V/50HZ/3PH

(2) Working temperature: 0℃~+40℃

(3) Working environment: clean and less dust

Structure:

According to JB/T 2257.2-92 "Technical conditions of sheet metal press brake bending machine" and GB/T 14349-93 "Accuracy of sheet metal press brake bending machine", the whole machine design is adopted. Meta-analysis calculation, computer-aided manufacturing (CAD/CAE/CAM) software for structural design, fully guarantee the structural strength and rigidity of each component;

This WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine adopts steel plate welding structure, tempering relieves stress, the CNC hydraulic press brake has good rigidity and stability, the whole frame has good rigidity, stable work, safe and reliable, and convenient operation, through electrical and the coordinated control of the hydraulic system achieves the ideal bending effect. Through the coordinated control of the special CNC system and hydraulic system of the E21 bending machine, the ideal bending effect is achieved.

(1) Slider part of this WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine adopts hydraulic transmission. The slider part is composed of slider, oil cylinder and mechanical stopper fine adjustment structure. The left and right oil cylinders are fixed on the frame, and the piston (rod) is driven by hydraulic pressure to move the slider up and down, and the mechanical stop is displayed by the E21 control system to adjust the value.

(2) The part of the worktable is operated by the button box in front of the worktable, so that the motor drives the material holder to move forward and backward, and the moving distance is displayed by the E21 digital display.

(3) Synchronization system: The customized Hydraulic Metal CNC Press Brake Bending Machine is a mechanical synchronization mechanism composed of torsion shaft and arm. The structure is simple, the performance is stable and reliable, and the synchronization accuracy is high. The mechanical stop is adjusted by the motor, and the E21 controller displays the value.

(4) The material blocking mechanism of this WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine is driven by a motor, and the two screw rods are driven to move synchronously through the sprocket. The E21 controller displays the size of the material blocking, which can be fine-tuned manually.

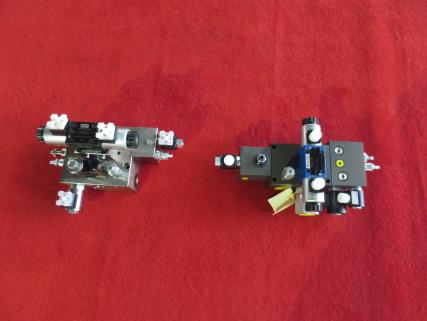

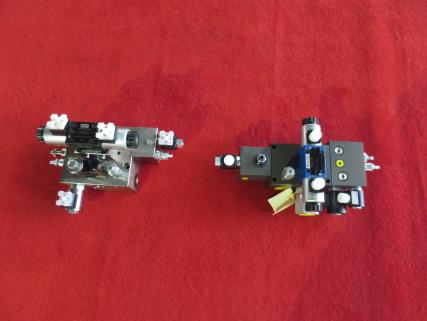

4.Hydraulic system of this customized hydraulic metal CNC press brake bending machine:

(1) The hydraulic valve group adopts Rexroth valve group;

(2) The main motor uses Siemens brands;

(3) The sealing ring adopts imported sealing ring, which has good sealing performance, reliable operation and long service life;

(4) Clear and intuitive oil level height and oil temperature display;

(5) The machine tool can work continuously under the rated load, the hydraulic system has no leakage and is continuously stable, with high precision.

5.Electrical control system:

(1) The electrical components use Siemens brand;

(2) Equipped with movable foot switch operation, with emergency stop function.

6. Slider synchronization control: WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine adopts torsion shaft synchronization control.

7. Mold: The mold can be designed and customized according to the actual process requirements of the user.

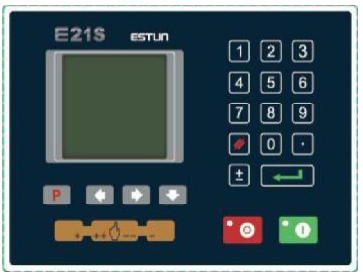

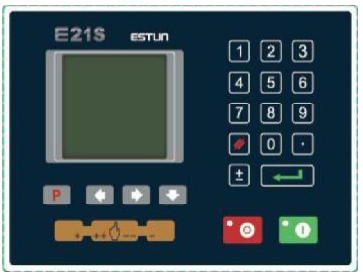

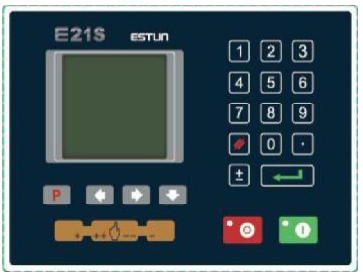

8.Control system: ESTUN E21 for WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine:

Note: E21 bending machine professional control function

(1)5.7-inch LCD screen, switch between Chinese and English, the screen font is clear and large.

(2)The system has 99 programs, each program has 25 steps. Multi-step automatic operation can be realized.

(3) Each axis can be moved manually

(4)operation screen can monitor each input, output signal, direct control of pressurization time

(5) Position control of the rear stopper of the bending machine and the position of the stopper in the oil cylinder.

(6)one-way positioning function, effectively eliminate the screw transmission gap.

(7) system has software limit function.

(8)power-off position memory function.

(9) The display scale factor can be set according to the screw pitch and transmission ratio. The display scale factor can also be automatically calculated by the CNC system through the teaching operation function, which is easy to operate.

(10)Withdraw and escape function, avoid the interference between the back stop device and the workpiece, and reduce wear.

(11) parameters are password protected.

(12) key detection function

(13) valve groups freely defined

(14) fault alarm in Chinese and English

9. Main configurations of WC67Y-160Tx3200 Customized Hydraulic Metal CNC Press Brake Bending Machine:

Gear pump:SUNNY |

Valve: Rexroth |

Electric elements:Siemens |

Motor: Siemens |

Main cylinder: Jianhu |

Mold: local famous brand |

Sealing rings: NOK |

Card sleeve connector: JS German |

Oil pipes: high precision tube |

Ball screw, linear guide |

Control: E21 |

local famous brand |